Rumored Buzz on Paper Machine

Wiki Article

How Paper Machine can Save You Time, Stress, and Money.

Table of ContentsThe Single Strategy To Use For Paper MachineThe Facts About Paper Machine RevealedWhat Does Paper Machine Mean?How Paper Machine can Save You Time, Stress, and Money.Paper Machine Things To Know Before You Get ThisAn Unbiased View of Paper Machine

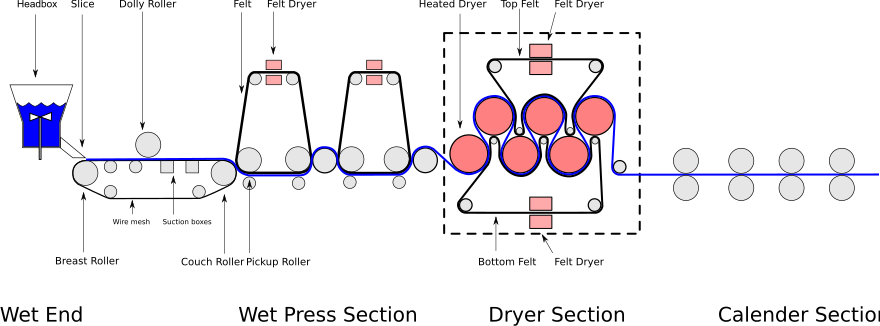

The standard procedure is an industrialised version of the historical process of hand paper-making, which might not please the needs of creating modern-day culture for big amounts of a printing and creating substratum.Paper devices generally contend the very least five distinct operational areas: Creating area, generally called the damp end, is a continual rotating wire mesh which eliminates water from the paper by drawing it out of suspension by means of vacuum. Press area, where the wet fiber internet passes in between big rolls filled under high pressure to press out as much water as possible.

Drying out gets rid of the water material down to a degree of regarding 6%, where it will continue to be at regular indoor atmospheric problems., where the dried paper is smoothed under high loading and pressure.

Paper Machine for Beginners

The sheet was after that raised off to be hung over a rope or wood rod to air dry. In 1799, Louis-Nicolas Robert of Essonnes, France, was given a license for a constant paper making machine. At the time, Robert was benefiting Saint-Lger Didot, with whom he quarreled over the ownership of the development.

, in 1803, complied with by one more in 1804. A 3rd maker was installed at the Fourdriniers' own mill at Two Waters.

Rumored Buzz on Paper Machine

The plant fibers made use of for pulp are made up primarily of cellulose and also hemi-cellulose, which have a propensity to create molecular links between fibres in the visibility of water.

A cylinder with cutting sides, or knives, as well as a knife bed is component of the loophole. The spinning cylinder presses the materials of the trough around consistently. As it decreases gradually over a period of hrs, it breaks the dustcloths up right into fibres, and cuts the fibres to the wanted size.

Little Known Questions About Paper Machine.

The seeds continue to be, surrounded by brief fibers recognized as linters for their short length as well as similarity to dust. Linters are also brief for successful usage in textile.Kraft pulp has directory remarkable stamina to sulphite and also mechanical pulps as well as kraft process spent gelatinating chemicals are less complicated to recuperate as well as regrow. Both chemical pulps as well as mechanical pulps may be blonde to a high brightness.

Lignin, like many various other substances that can divide fibres from one an additional, acts as a debonding agent, decreasing stamina. Stamina also Learn More Here depends on preserving lengthy cellulose particle chains.

9 Simple Techniques For Paper Machine

It is typically blended with virgin pulp - paper machine. At incorporated pulp and paper mills, pulp is generally saved in high density towers before being pumped to equip prep work. Non integrated mills utilize either completely dry pulp or wet lap (pushed) pulp, usually gotten in bales. The pulp bundles are slushed in a [re] pulper.The p, H is controlled and different fillers, such as lightening representatives, dimension and also wet toughness or dry toughness are added if essential. Extra fillers such as clay, calcium carbonate as well as titanium dioxide rise opacity so printing on reverse side of a sheet will certainly not sidetrack from material on the obverse side of the sheet.

Things about Paper Machine

From there it is usually diluted to regarding 4% consistency before being pumped to an unrefined supply chest. From the unrefined supply upper body supply is again pumped, with consistency control, via a refiner.This action deciphers the external layer of the fibers, creating the fibrils of the fibres to partly remove as well as bloom external, raising the surface to promoting bonding. Refining therefore enhances tensile toughness. Cells paper is fairly raw whereas packaging paper is a lot more extremely refined. Improved supply from the refiner after that mosts likely to a polished stock breast, or mix upper body, if made use of therefore.

Report this wiki page